Page 6 of 17

Re: Convair YF2Y-1 Sea Dart

Posted: January 21st, 2016, 3:10 pm

by Alex Jones

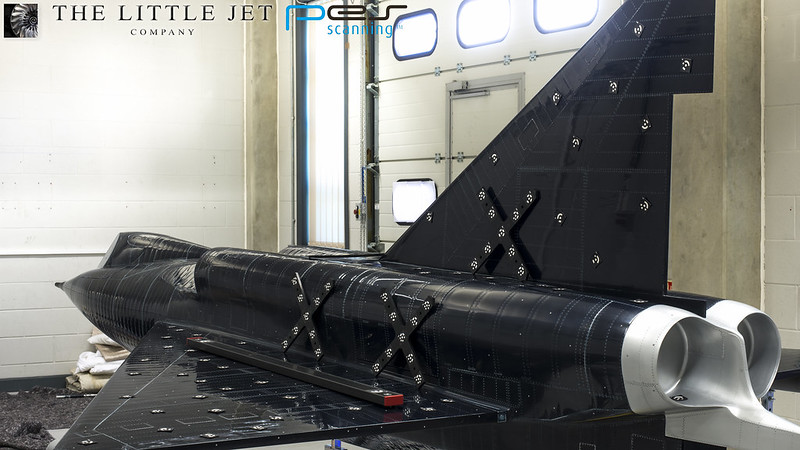

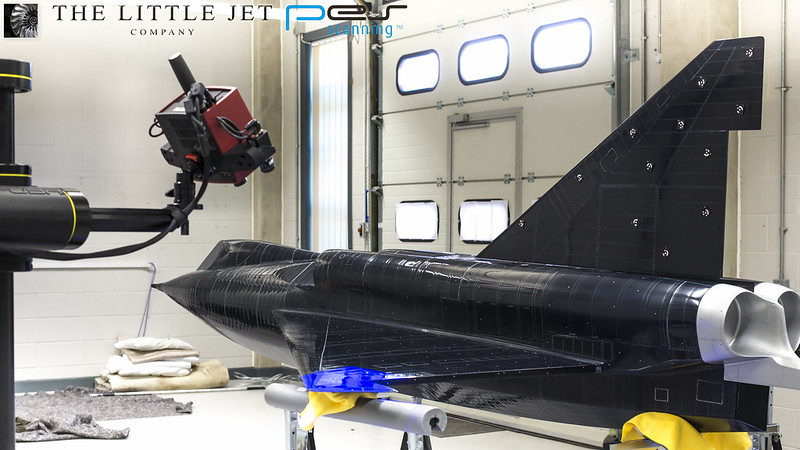

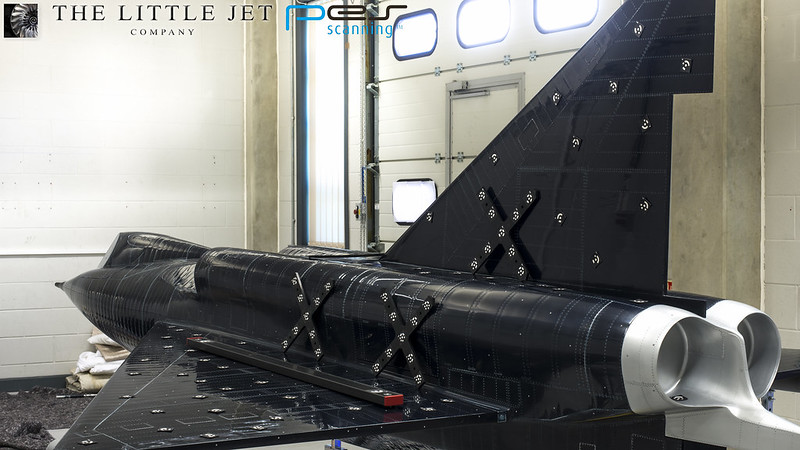

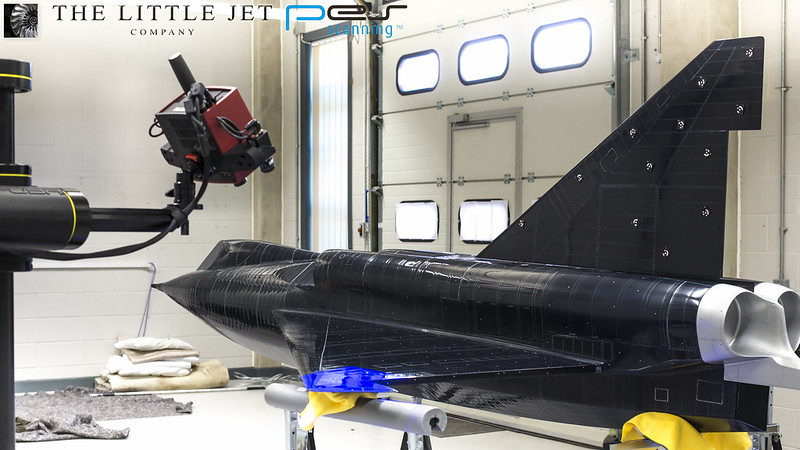

I forgot to mention that the above photos are a mock up and a quick demo only. It is a good representation of the process however the whole model will have to be sprayed with titanium dioxide before the scan. At the moment the pattern has the worst two properties for scanning, dark and glossy... The spray will allow the scanner to capture its data correctly with minimal noise. Its a very fine layer and on experimentation does not effect the detail built into the pattern.

Re: Convair YF2Y-1 Sea Dart

Posted: January 21st, 2016, 3:12 pm

by Alex Jones

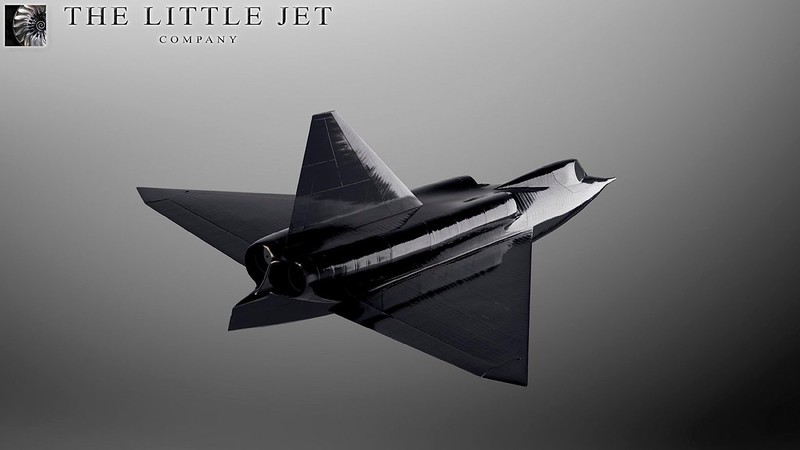

A quick reminder as to the phase we are at with our SeaDart.

The next few weeks are going to be really interesting with several design meetings planned with the tooling firms and part manufactures along with a few specialist hydraulic companies. I'm very interested to see what we can come up with on the hydraulic side of things. The sequencing of the for and aft skis is critical in the retraction and extension sequences. Along with the need of full instantaneous proportional control of the water rudder/brake which we would also like to be hydraulic due to the forces involved in its deflection at speed in the water.

Project

Project by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: January 23rd, 2016, 8:58 pm

by Alex Jones

I didn't realise you couldn't edit posts, as I moved the Flickr images they are no longer available so thought I'd post this again so the images are on the thread. Let me know if you can edit previous posts I may have missed the option.

The project should move quite swiftly now as we hope to get a basic prototype complete for May. This can be evaluated here in the UK ready to send abroad for flight testing although we are still in talks with the appropriate aviation authorities as this model breaks almost every rule in the book in most countries. I consider myself lucky to have such a good large model scene here in the UK. This is run by the LMA on behalf of the CAA which allows us to do almost anything with the correct oversight, inspections and flight tests. So a quick thank you to everyone involved in the LMA.

With phase 1 & 2 completed on schedule we can now move forward with the composite design. The next few months won’t actually see anything physical being built except the tooling. The time will be spent in CAD designing the internal structures, ski mechanisms and lay up designs etc… To facilitate this we are in the process of having the pattern scanned using blue light technology. There are many advantages to this that justify the significant expense of the process especially considering the resolution required to capture every rivet and panel deformation in the pattern.

Ordinarily on a project like this you would start with a CAD model, CNC the pattern and take the tooling from this. We don’t have the luxury of a CAD model which is where the scanning comes in. With the scan data we can accurately design all the internal structure but not only this we can now accurately determine the weight of the model before its built. This will significantly speed up the design process as weight it critical in determining how the model presents on the water. CG, ballast tanks, component position and many other areas of uncertainty can be designed in from the outset. Undoubtedly there will be changes in the design as there nearly always is but this allows us to get much closer to a finished model first time out.

The team at PES Scanning gave me a quick work flow run through of how they will scan the pattern along with a short demonstration starting with the photogrammetry. The scanning team have been very helpful through the whole process and I’m looking forward to seeing the results.

_DSC9626

_DSC9626 by

Alex Jones, on Flickr

_DSC9639

_DSC9639 by

Alex Jones, on Flickr

_DSC9643

_DSC9643 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: February 1st, 2016, 10:43 pm

by Alex Jones

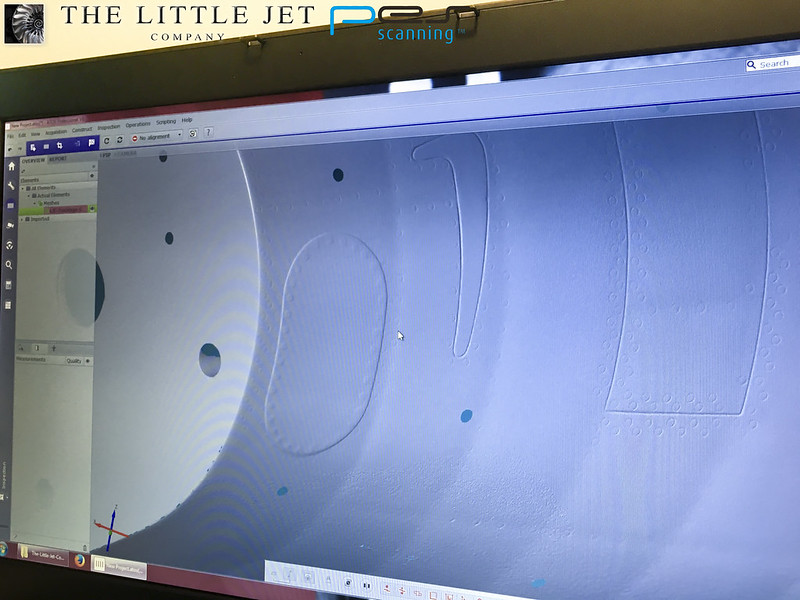

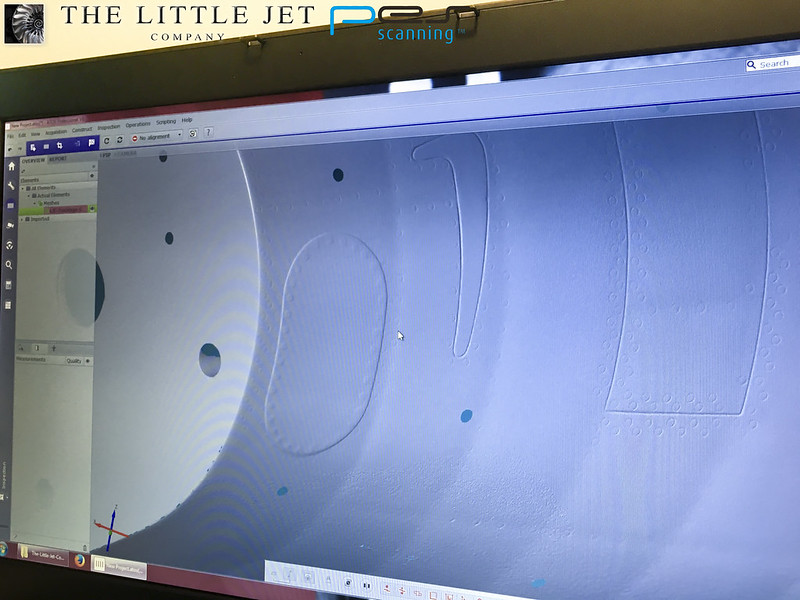

PES Scanning have now finished the SeaDart scan. I’m amazed at the level of detail they have captured and I’m excited to see all of the data later this week.

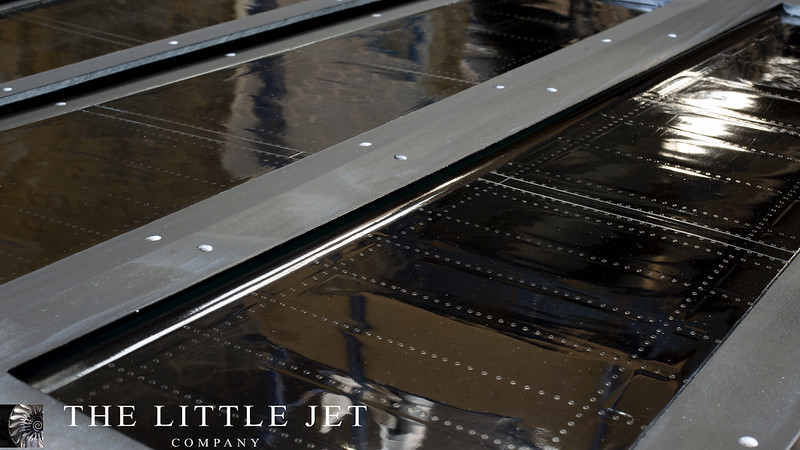

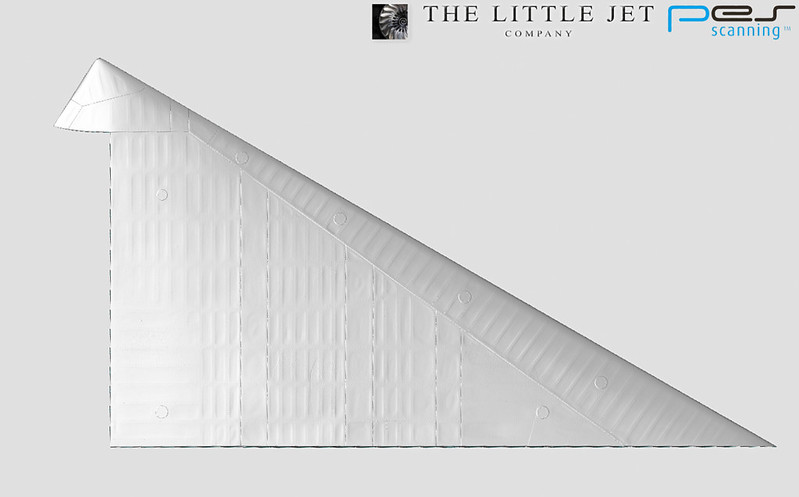

This is a low resolution screen grab but should give you an idea of the level of detail the guys at PES scanning have managed to capture. This shows the underside of the right wing. The wings on the full size took a massive battering and looking at our research photos from the 50's FighterAces have managed to emulate this very well indeed.

Starboard-Wing-6

Starboard-Wing-6 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: March 26th, 2016, 6:07 pm

by Alex Jones

I know I’ve been a little quiet with regard to this project but I’ve been working nearly full time since my last post on the aircrafts internal, tooling and layup designs along with manufacturing workflows etc…

We’ve been managing all the companies involved so we can all come together at the right time with the correct designs and parts allowing us to build the first prototype with as few issues as possible. I’ve lost count of the number of miles I have driven to various design meetings and touring possible manufacturers facilities.

We are now at a stage where I’m very happy with all the companies involved and think we can make something spectacular. The tooling and parts manufacturers are very enthusiastic about the project and to see that our design will be produced along side parts at the highest level of composite specification is very exciting. I would love to tell you what sort of things these guys are doing and for who but unfortunately almost all the work these companies do is based on non disclosure agreements but the level of detail and the quality of the composite parts we’ve seen being produced is staggering and far removed to what we are used to in our models.

PES Scanning have done a great job with the scan at what was a very high resolution. We have captured every panel deformation and every rivet. The resolution was so high that the scanner picked up the titanium dioxide spray but the team also encountered some noise in the data which had to be removed by hand. This is mainly due to the pattern having the worst two properties possible for scanning which is dark and glossy. Even so the results are beyond what I had expected. The below picture shows the front portion of the fuselage in the process of being cleaned. The file contains over 170 million triangles and is in the region of 22GB in size.

IMG_0544

IMG_0544 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: March 28th, 2016, 1:59 pm

by Alex Jones

The Pattern was displayed at the Advanced Manufacturing Park home to parts of AMRC Boeing and Rolls Royce along with some really innovate engineering companies. We’ve been asked to display the finished model at the Manufacturing Park as the pattern created a lot of interest in the project. We will also be giving several talks on the models development later in the year...

Some large companies have become interested and are helping us with various parts of the model. Rolls Royce patented technology is being designed into areas of the project and some other sponsorship opportunities have arisen which if they pan out are very exciting!

While scanning the pattern there was some superficial damage caused. Having a flawless pattern before we start tooling is essential so I drove it back to FighterAces who made the repairs to their usual high standard and many thanks to the team for fitting the model back in to their busy schedule, it was much appreciated!

The pattern is now now back to looking its best.

_DSC9624

_DSC9624 by

Alex Jones, on Flickr

Dave Wilshere from Motors & Rotors here in the UK has been very helpful and managed to get us a P300RX(G) in short order. The service I received through Dave was second to none and I’m looking forward to having his experience cast over some of our other projects we have in the pipeline. This P300 is destined for another project but it did allow us to scan it as a space saver in CAD which will allow for a more accurate design.

The P300RXG held against the pattern.

JetCat P300RX(G)

JetCat P300RX(G) by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: August 6th, 2016, 7:35 am

by Alex Jones

Hi Guys,

Sorry I haven’t updated the thread for a while but we have been doing lots behind the scenes on the SeaDart and a few other projects.

Progress is going well but has been delayed a little. The tooling is looking really good but we spent some time with the company involved experimenting with release agents trying to find the right combination for our pattern and the resin system we are using. We now have a resin system with a very low endothermic reaction helping to maintain the dimensional stability of the pattern. The resin is a high temperature system allowing us to use the tooling in the autoclave which means we can make the parts using the latest in prepreg materials.

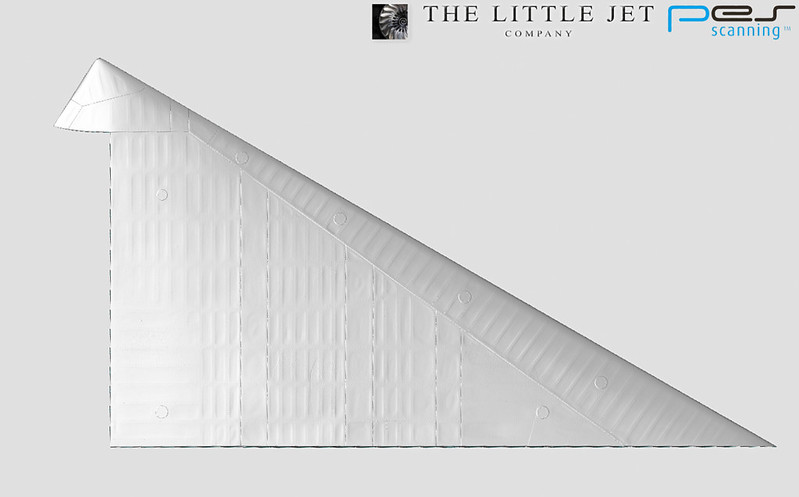

Another delay and after much thought mainly due to cost I decided we really needed cradles for the tooling process on the wings, fin and elevons. This was the only way I could guarantee there would be no movement in the wing during the process. With this decided we rapid surfaced the wings in CAD using the scan data and CNC’d the cradles using these surfaces. The result is impressive and I will of course upload photos of the tooling and cradles once it has all been made. Our next projects won't suffer from these issues as they will CNC'd patterns from the start using scan data captured from the full size.

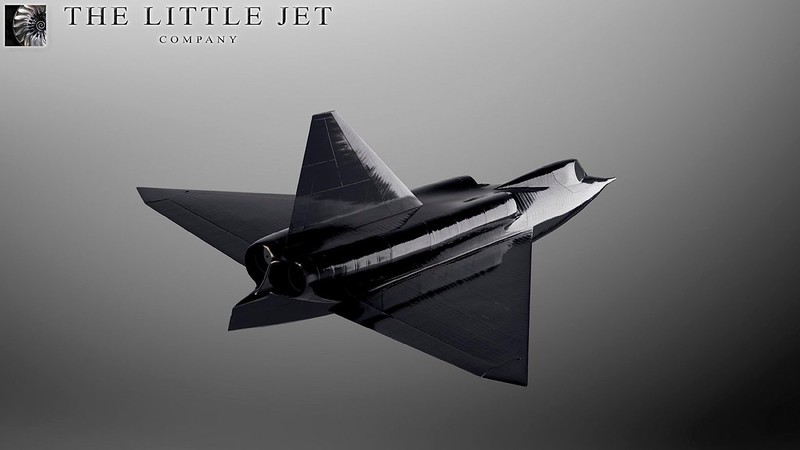

To round the scanning phase off I thought I’d attach an image which I made using the scan data. This is an STL file rendered in CAD, to put the detail captured into context this image is only 100Mbs of data. The raw data file size is 22GBS....

f9751db8-b159-488f-83cd-a68d354cec6a

f9751db8-b159-488f-83cd-a68d354cec6a by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: August 6th, 2016, 7:40 am

by Alex Jones

Great progress on our SeaDart tooling! To give you an idea of scale I could crawl into this rear fuselage section and lie down.

_DSC0750

_DSC0750 by

Alex Jones, on Flickr

_DSC0735

_DSC0735 by

Alex Jones, on Flickr

_DSC0748

_DSC0748 by

Alex Jones, on Flickr

Although the pattern has sustained superfical damge all the tooling has turned out very well. We're pushing hard to get the CAD work finished so we can start manufacturing parts towards the end of August. We're currently running through the layup designs which are a mix of e-cloth, carbon and kevlar. The nice thing about the fuselage sections is we can make them seamless giving the finished parts more strength than the traditional joining of two halves. We will still have flashing to remove where the tools join but no seam.

I'm taking the pattern back to FighterAces next week where it will be put on display.

Cheers

Re: Convair YF2Y-1 Sea Dart

Posted: August 9th, 2016, 9:29 am

by Alex Jones

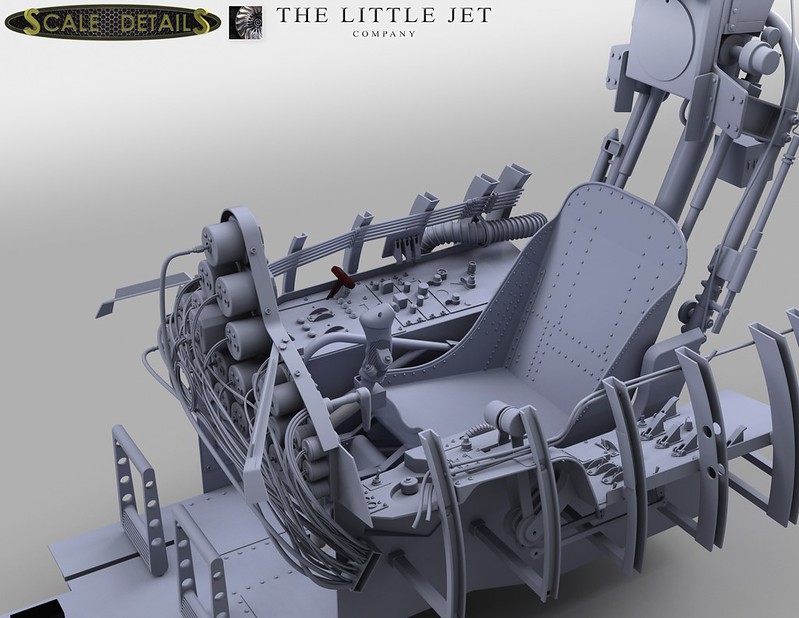

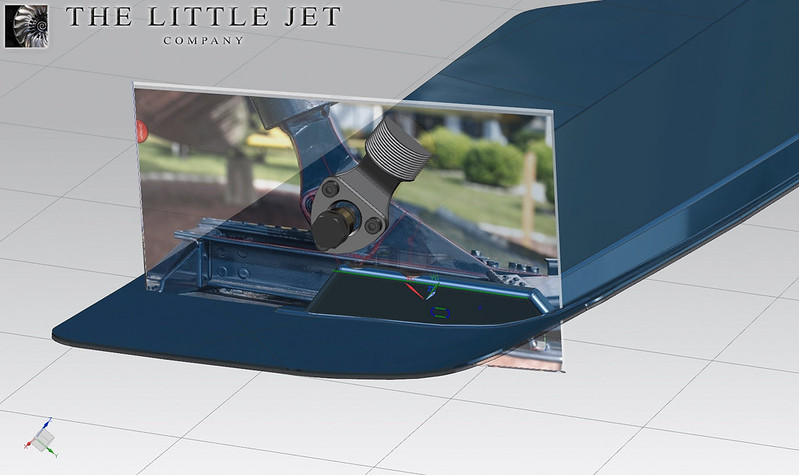

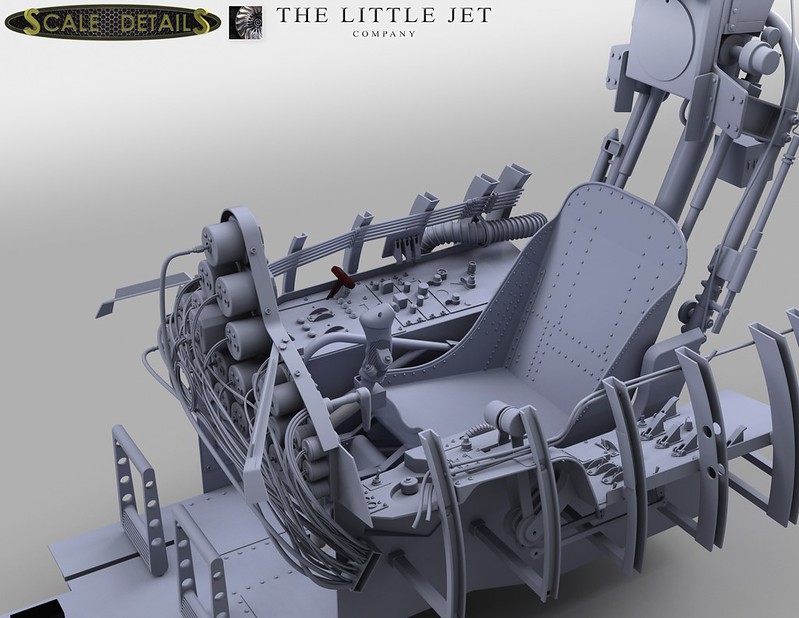

With the cockpit designs underway I set about designing a gimbal mechanism so the control stick could be driven, this in turn will move the pilots arm and be integrated into the main cockpit.

Stick_Gimbal_Mechanism._2016-May-08_12-49-25PM-000_CustomizedView3563719658

Stick_Gimbal_Mechanism._2016-May-08_12-49-25PM-000_CustomizedView3563719658 by

Alex Jones, on Flickr

Stick_Gimbal_Mechanism._2016-May-08_12-50-26PM-000_CustomizedView13184466950

Stick_Gimbal_Mechanism._2016-May-08_12-50-26PM-000_CustomizedView13184466950 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: August 12th, 2016, 6:38 am

by Alex Jones

Re: Convair YF2Y-1 Sea Dart

Posted: October 30th, 2016, 12:05 pm

by Alex Jones

It’s been a while I know… We haven’t been idle though, in fact we have been busier than ever. We have some really cool stuff in the works for 2017 which I can’t wait to share with you all along with our newly built website next year.

The SeaDart is progressing well although the CAD work is taking much longer than anyone anticipated. This is an expensive undertaking so spending the extra time in CAD before we start manufacturing parts is a sensible decision. We have agreed to have this work finished before the Christmas break so we can start manufacturing the main components in January.

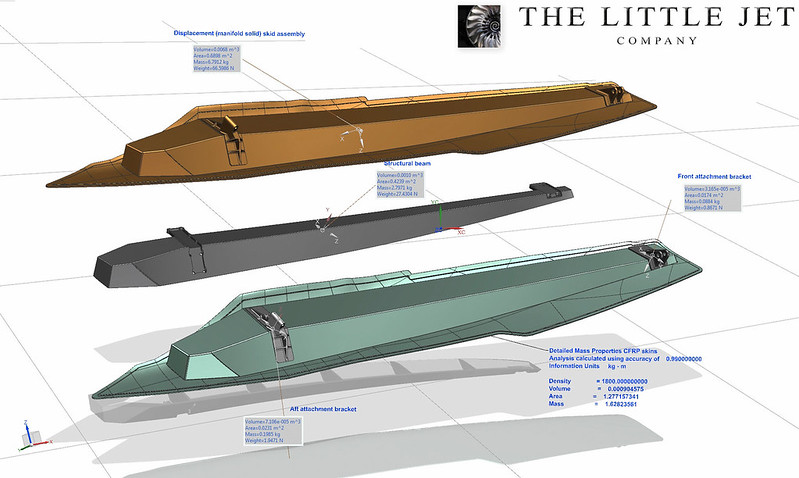

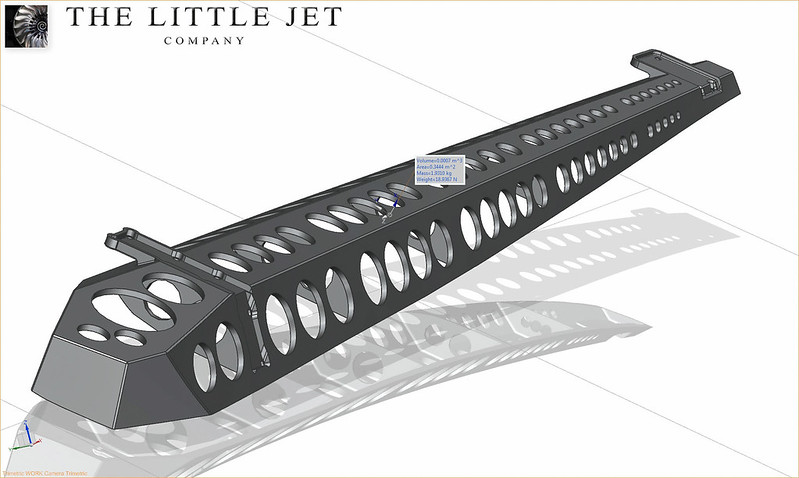

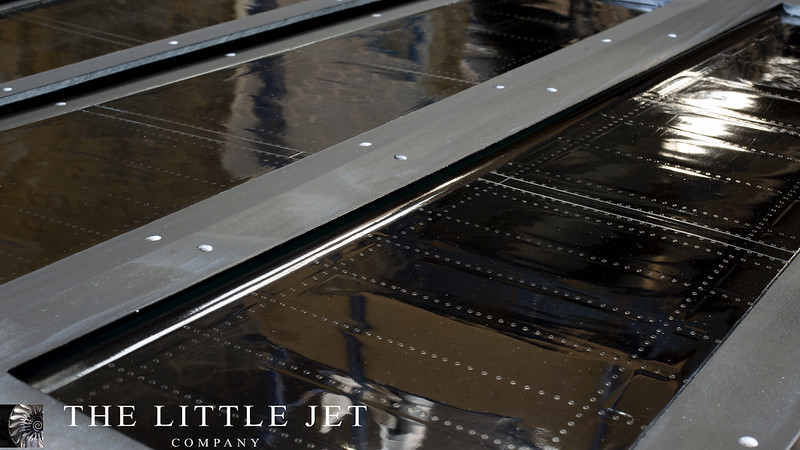

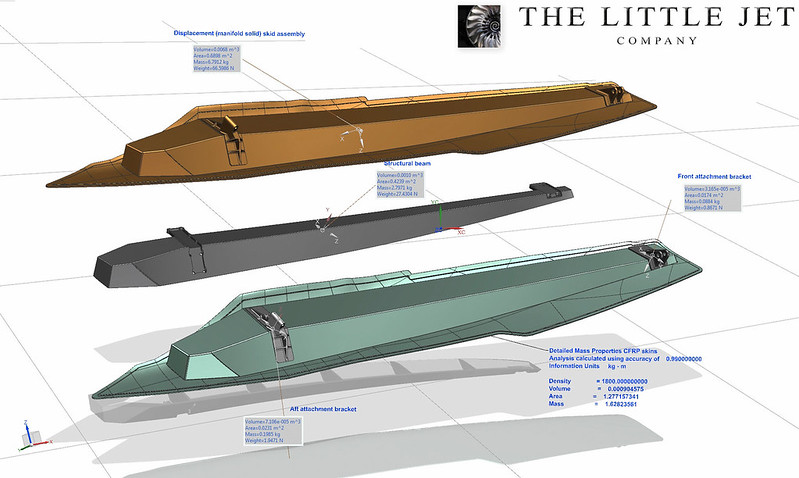

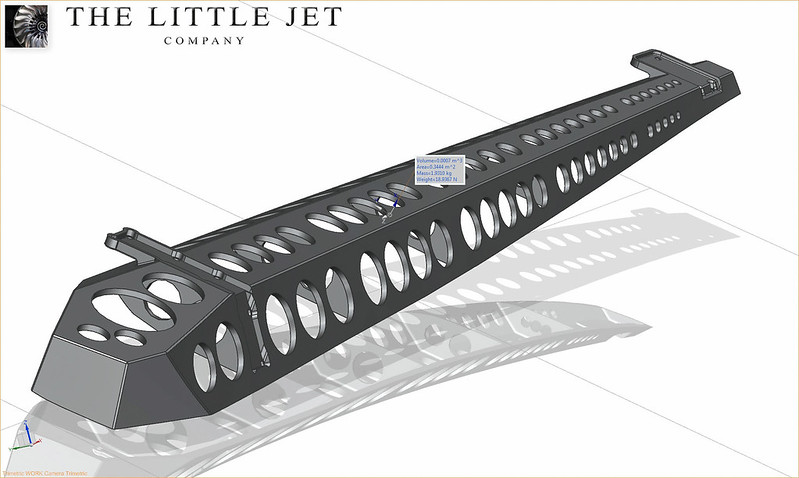

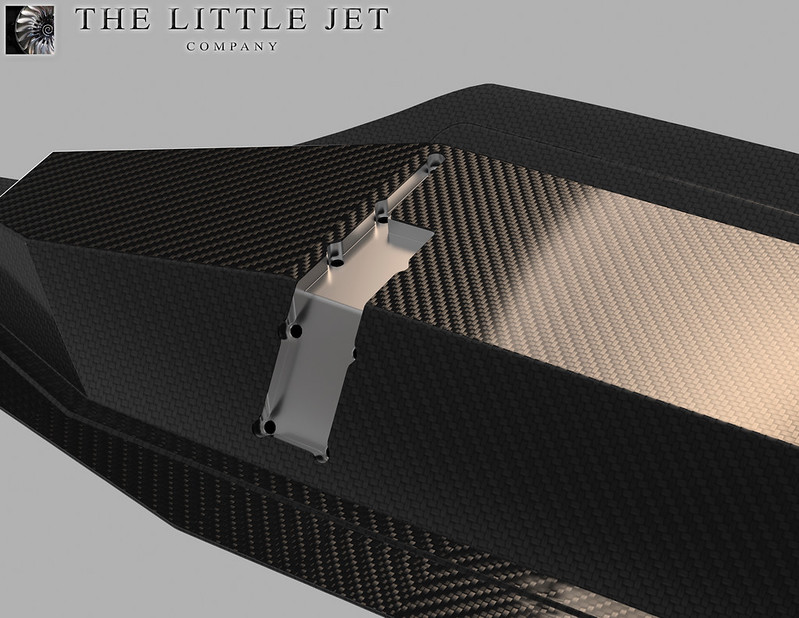

The design work on the skis has been completed and we are in the process of having these manufactured. The skis are made in three parts. A bottom skin consisting of a 1mm Carbon/Kevlar layup. All exposed edges have a 100% carbon layup integrated to enable a good finish on the pulled parts. The center of the ski consist of an aluminium sub-frame which is capped off by another carbon skin. The substructure ties the forward and aft ski attachment points together.

Ski for weight analysis_x_t wb

Ski for weight analysis_x_t wb by

Alex Jones, on Flickr

Ski beam weight reduction

Ski beam weight reduction by

Alex Jones, on Flickr

The patterns for the top and bottom ski skins have been machined from tooling block and are on their way to Fighteraces for detailing. There are thousands of raised riveted to add to these skis.

_DSC8310

_DSC8310 by

Alex Jones, on Flickr

Once the patterns are detailed we will make Carbon LTM tooling enabling us to get some amazing parts using pre-preg layups.

TLJC SD Ski Construction 1

TLJC SD Ski Construction 1 by

Alex Jones, on Flickr

TLJC SD Ski Construction 2

TLJC SD Ski Construction 2 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: October 30th, 2016, 1:08 pm

by Alan Cantwell 1131

This has got to be the most complex, not to say expensive model aeroplane in the history of modelling, fascinating!

Re: Convair YF2Y-1 Sea Dart

Posted: October 30th, 2016, 5:23 pm

by Alex Jones

Thanks Alan, I'm glad your enjoying the build...

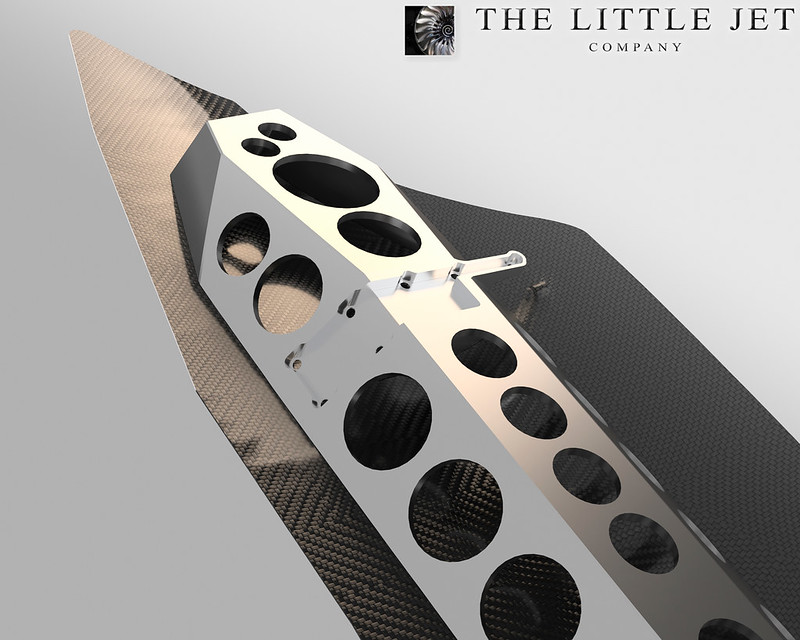

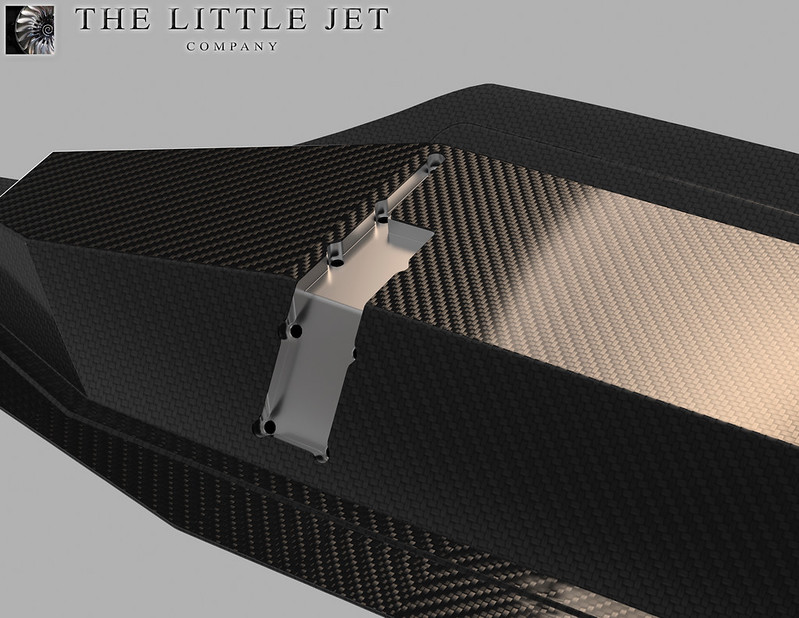

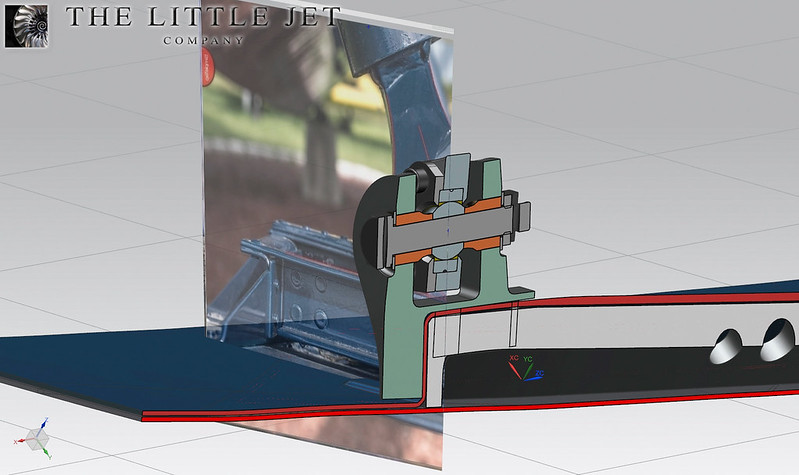

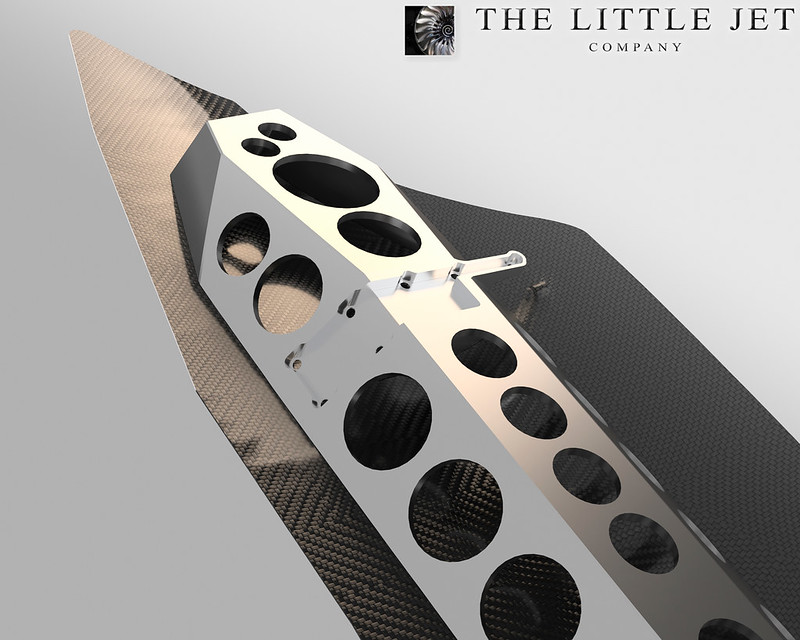

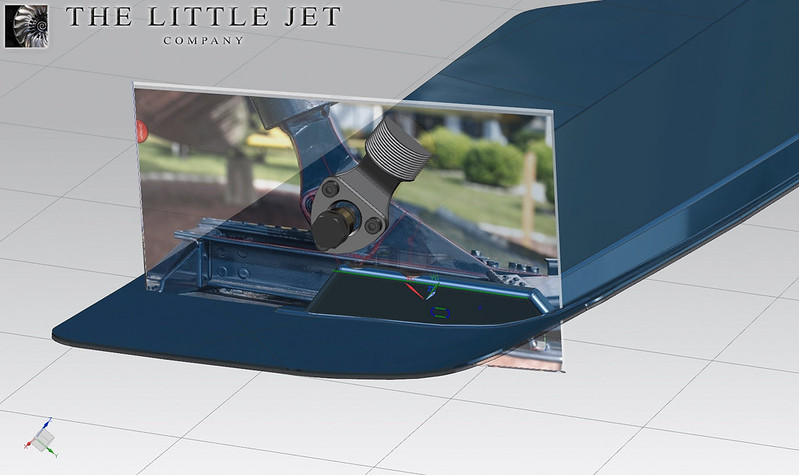

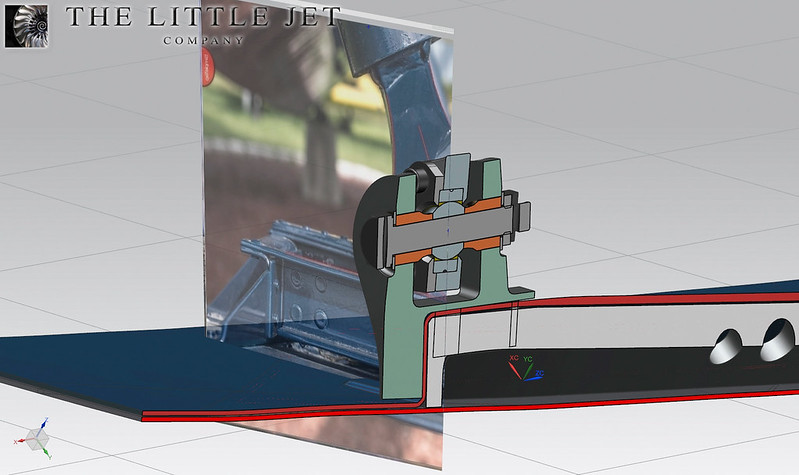

The level of detail that the client is specifying is incredible! For example the forward attachment for the ski is as close to 100% as possible. Every part is bespoke and this requires carful thought so what we design can in fact be manufactured. This is just one small part of hundreds which is one of the reasons we've spent nearly 4 months solid on the design work.

TLJC Fwd Bracket

TLJC Fwd Bracket by

Alex Jones, on Flickr

TLJC Fwd Bracket

TLJC Fwd Bracket by

Alex Jones, on Flickr

TLJC Fwd Bracket XSesction

TLJC Fwd Bracket XSesction by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: October 30th, 2016, 7:42 pm

by Alan Cantwell 1131

Ive been all round the one at the Florida air museum, its a complex machine, keep it coming,

Re: Convair YF2Y-1 Sea Dart

Posted: October 31st, 2016, 10:49 am

by Alex Jones

Hi Alan

We visited that aircraft back in 2014. Yes its certainly complex... We have all the problems of a twin turbine jet, Hydroski and boat all rolled into one. The ski retraction mechanism is just one big headache the main problem is the geometry once the ski ties the forward and aft mechanisms together. Nearly 80% of all our design budget has been taken up with this part alone.

We took lots of research pictures which you can view here if your interested.

https://www.flickr.com/gp/tljc/D0CB07This is some of the work on the rear mechanism.

Client Progress Images

Client Progress Images by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: November 6th, 2016, 5:38 pm

by Alex Jones

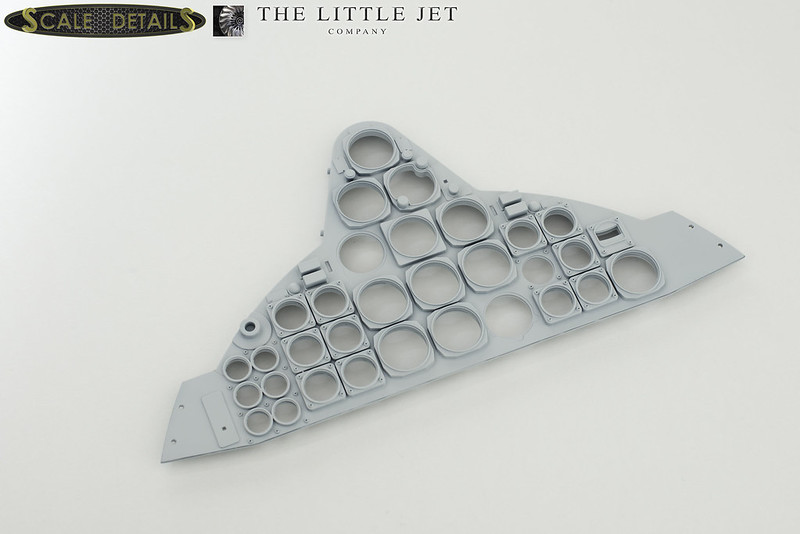

It's about time I showed you all some real parts rather than endless screen grabs of our CAD work... although there are plenty more of those to come!

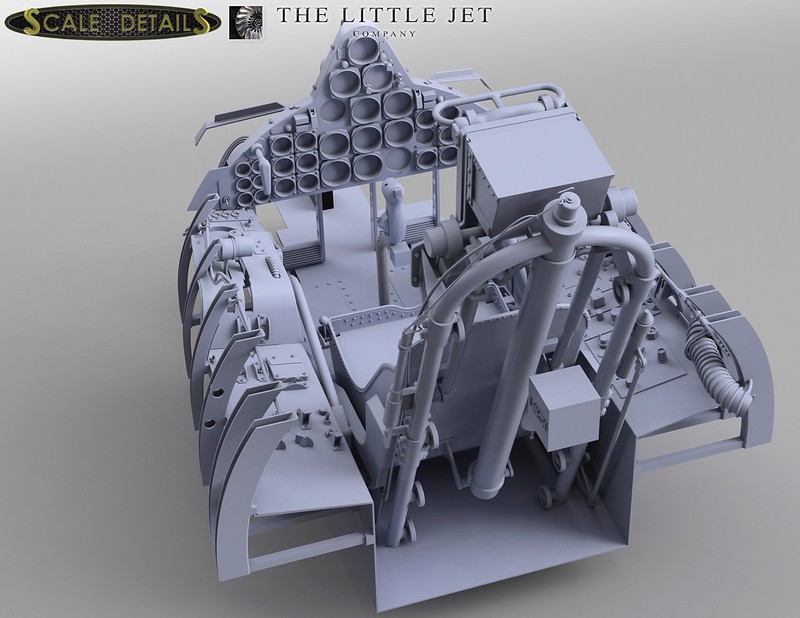

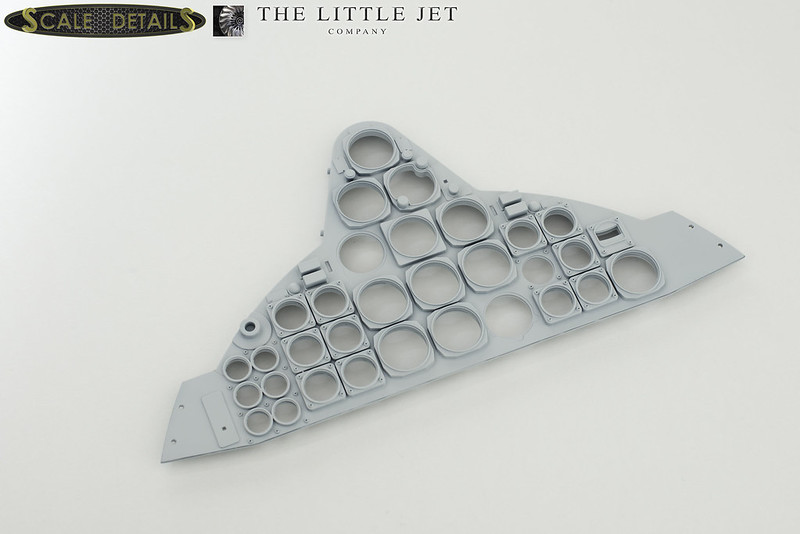

A render of the instrument panel to remind you all what it looked like then a few shots of the real parts.

Sea_dart__cockpit_1.4_2016-May-29_06-05-33PM-000_CustomizedV iew13785577041

Sea_dart__cockpit_1.4_2016-May-29_06-05-33PM-000_CustomizedV iew13785577041 by

Alex Jones, on Flickr

CAD work was done by the very talented Anton Robertsson from Scale Details in Sweden, with some minor modifications in house here at The Little Jet Company. The parts are all made and finished by us here in the UK.

TLJC SD Instrument panel

TLJC SD Instrument panel by

Alex Jones, on Flickr

TLJC SD Instrument panel

TLJC SD Instrument panel by

Alex Jones, on Flickr

TLJC SD Instrument panel

TLJC SD Instrument panel by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: February 1st, 2019, 5:46 pm

by Alex Jones

I had completely forgotten about this thread until reminded today... Plenty has happened since my last post.

The team have been working flat out on this and a number of other large projects. The SeaDart is progressing well and we hope to do the water based testing in the summer. Depending how this goes flying will be a few months after that.

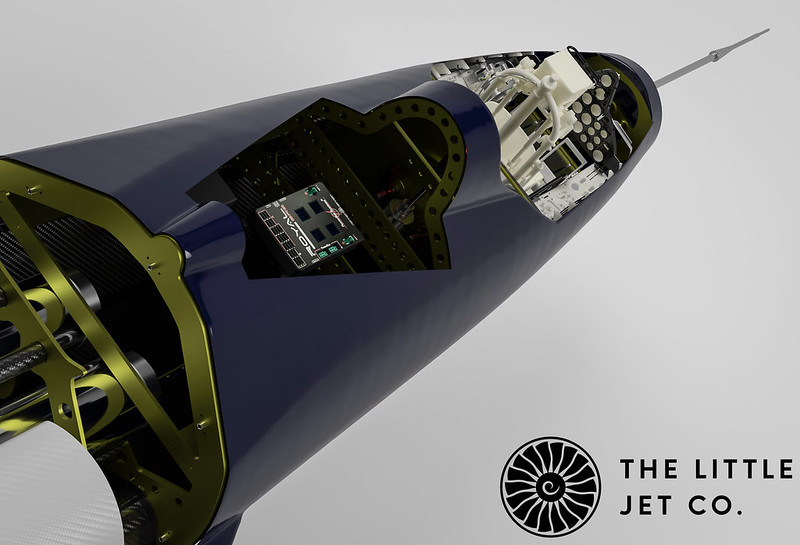

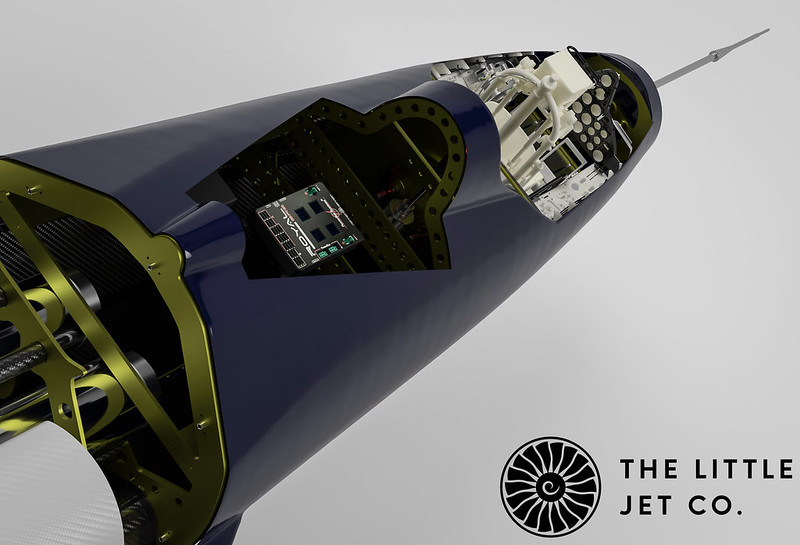

A few teaser shots, the first are a few basic photos of the cockpit. This is a prototype only and not representative of the finished parts in terms of quality, also this has the bare minimum of detail included and is being used by a company in the US to design the animatronic pilot.

_DSC1814

_DSC1814 by

Alex Jones, on Flickr

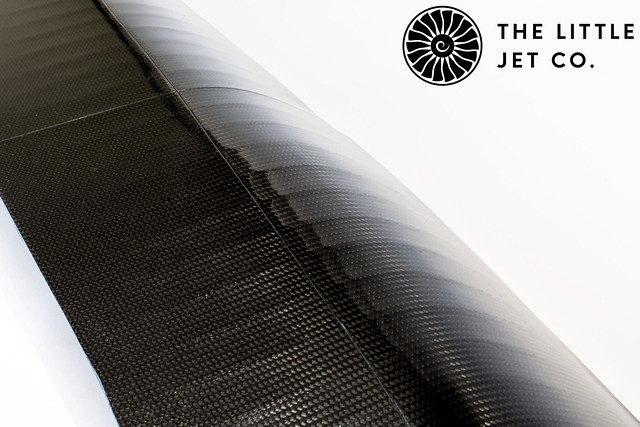

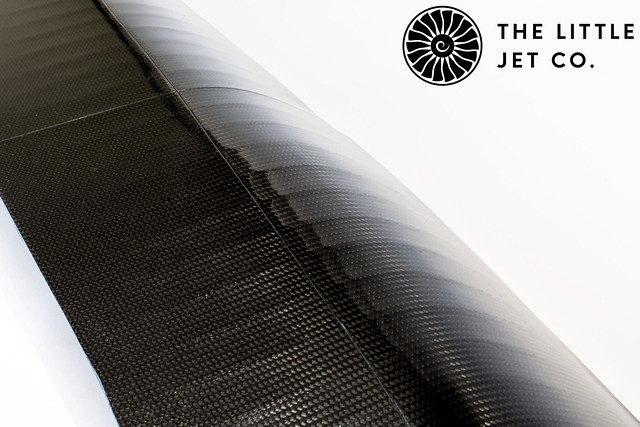

This is an image of the actual manufactured part for the bottom skin of the ski.

_DSC1823

_DSC1823 by

Alex Jones, on Flickr

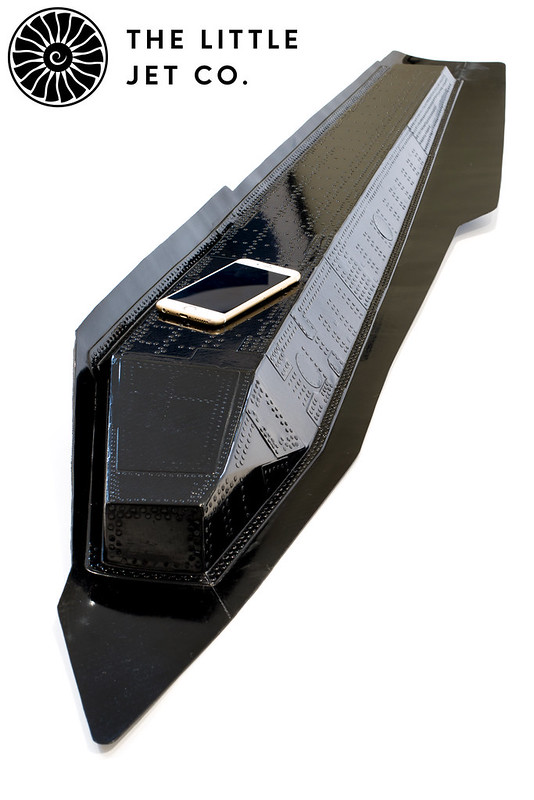

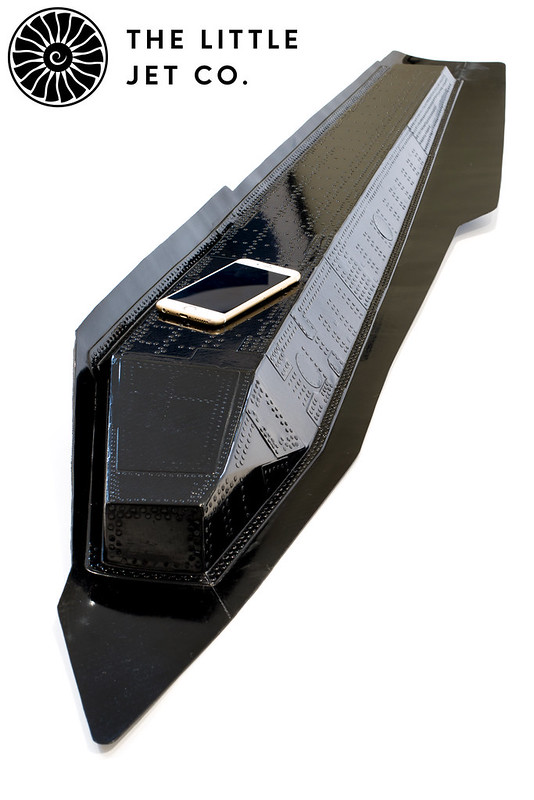

One more shot of the top ski showing some of the detail Fighteraces worked so hard to include on the patterns. The standard size i-phone hopefully gives some scale. The skis are 1.6 meters (5'3") in length and both these components are pre-preg carbon cloth cured in an autoclave.

_DSC1821

_DSC1821 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: February 1st, 2019, 5:48 pm

by Alex Jones

Some of the first machined components being installed into the cockpit base on our YF2Y-1 Sea Dart project. This will facilitate a full working cockpit with animatronic pilot.

_DSC3386

_DSC3386 by

Alex Jones, on Flickr

TLJC

Re: Convair YF2Y-1 Sea Dart

Posted: February 1st, 2019, 5:49 pm

by Alex Jones

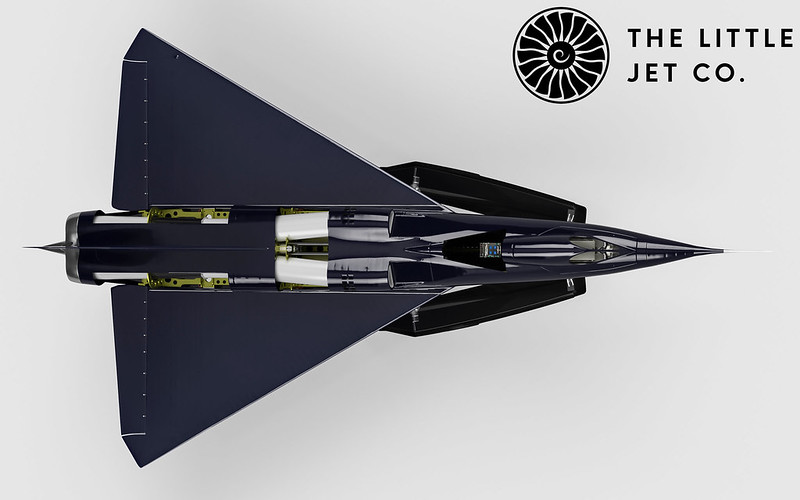

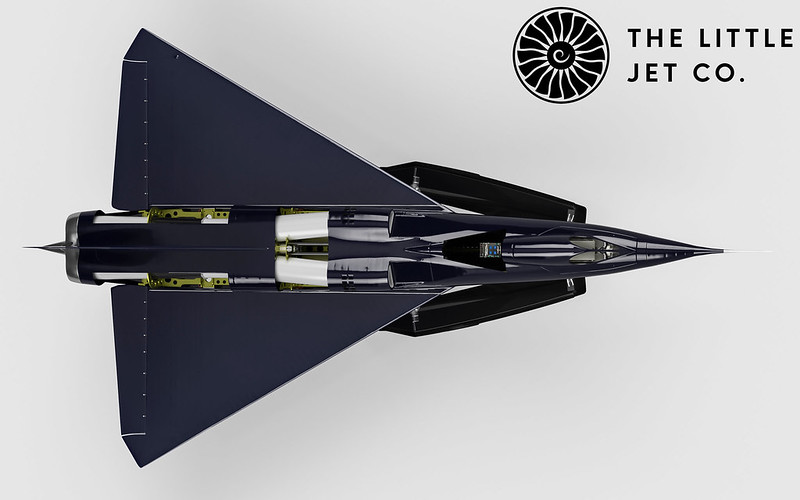

The CAD model is complete down to every component, ECU, TTU’s, batteries servos, actuators and so on… Everything has been modelled to ensure the best of fits. This in turn allows us to design a structure that can easily accommodate all the ancillary equipment. This also includes wiring looms and in this case electrical conduits have been designed in that double up as structural support. Things are further complicated by the nature of the model. This has been designed to operate solely from water so everything needs to be sealed. From the apertures that accommodate the gear and elevon actuators to a completely sealed bypassed ducting system.

TLJCSD 2

TLJCSD 2 by

Alex Jones, on Flickr

TLJC-01-10-001-SEA-DART-ASSEMBLY-PROV_2017-9157856870

TLJC-01-10-001-SEA-DART-ASSEMBLY-PROV_2017-9157856870 by

Alex Jones, on Flickr

After much testing with various materials, layups, cycle times and pressures in the clave we have finally hit the sweet spot. All the components are now being manufactured with our composite partner who’s support in this project has gone well beyond what I had expected. The results are flawless so I’m very happy indeed. The composite parts are a mixture of monolithic layups, some components with core and some not. Various materials have been used including carbon, kevlar and e-glass. What we are doing that perhaps people may not have seen on an RC jet is that all the composite components are using pre-preg fabrics. This means we don’t have a gelcoat. Each component has the correct amount of resin pre-pregnated into the cloth as designed so you end up with the lightest yet strongest component possible. We have taken the time to get this just right as these techniques and materials will be used in our commercial projects next year which we very excited about.

_DSC3384

_DSC3384 by

Alex Jones, on Flickr

Re: Convair YF2Y-1 Sea Dart

Posted: February 1st, 2019, 5:50 pm

by Alex Jones

Here are some manufactured components starting with the forward ski mechanism. This has been manufactured from Titanium (TI-6Al-4V), Stainless Steel (SS316L) and Aluminium (6082-T6/7075-T6). The darker alloy is the TI with the bottom pivot made from SS the rest is T6.

I'm really please that everything fitted together perfectly with zero slop yet very free movement.

TLJC FWD SKI MECH View 1

TLJC FWD SKI MECH View 1 by

Alex Jones, on Flickr

TLJC FWD SKI MECH View 2

TLJC FWD SKI MECH View 2 by

Alex Jones, on Flickr

TLJC FWD SKI MECH View 3

TLJC FWD SKI MECH View 3 by

Alex Jones, on Flickr