Don't worry Dave we can always give him a push if it comes to it!

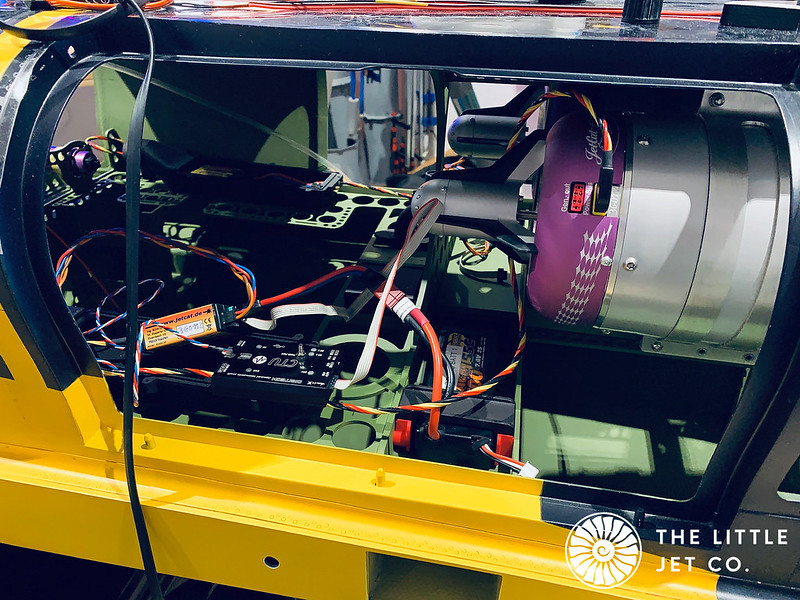

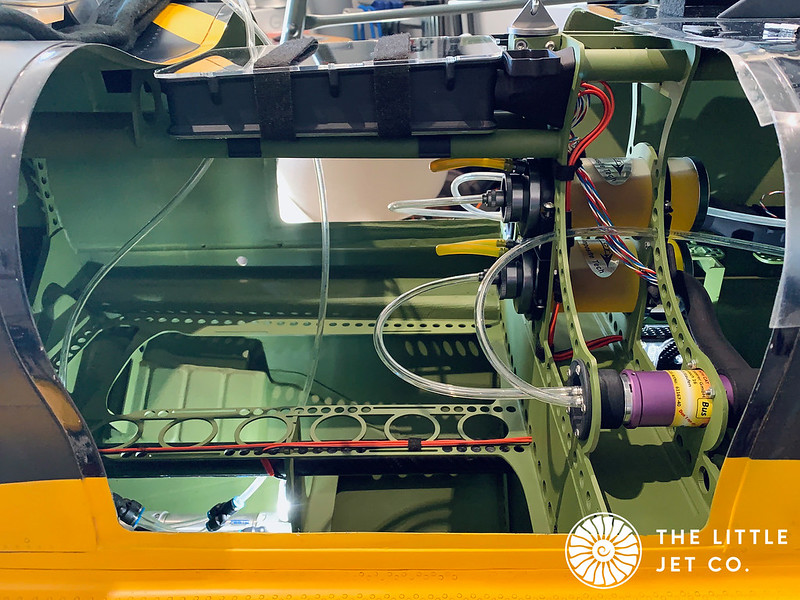

While things are easy to access I tested the fuel systems on both tanks. It’s a good opportunity to check for any small leaks, it beds the pumps down especially as they can run at full thrust voltage and lastly I can fine tune the pump factors so the fuel state telemetry is accurate. It is not always necessary on models to do this as access is easy and it’s not a big job to change things although this isn’t the case in this instance. Usually leaks appear at higher voltages and if you’ve purchased a used turbine pay close attention to the barbs on the pumps as people like to cut tubing off with a scalpel. This often leaves very small indents on the barb ridges and it will leak on thrust setting above idle.

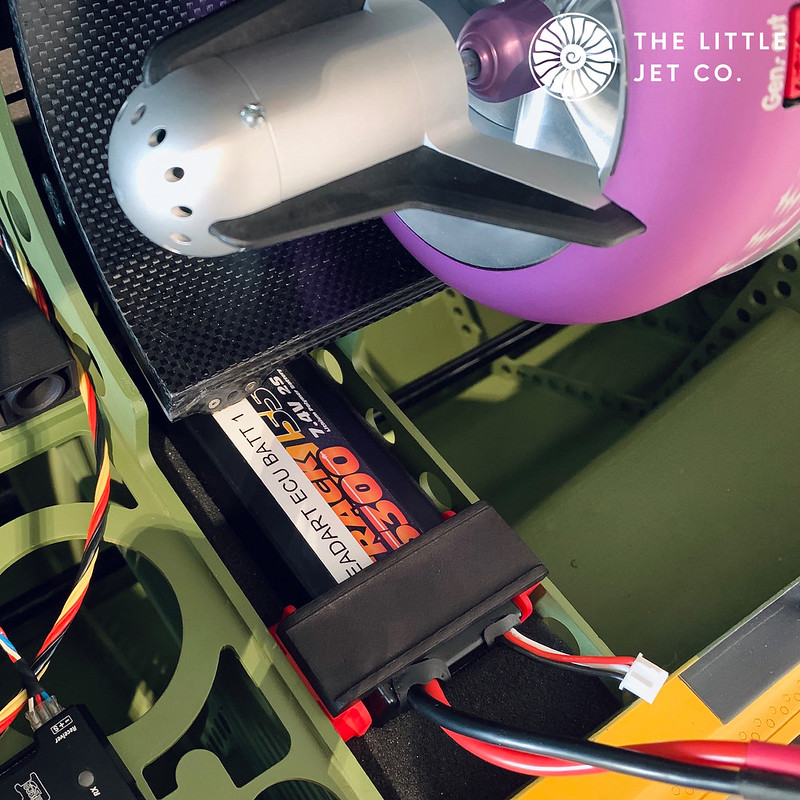

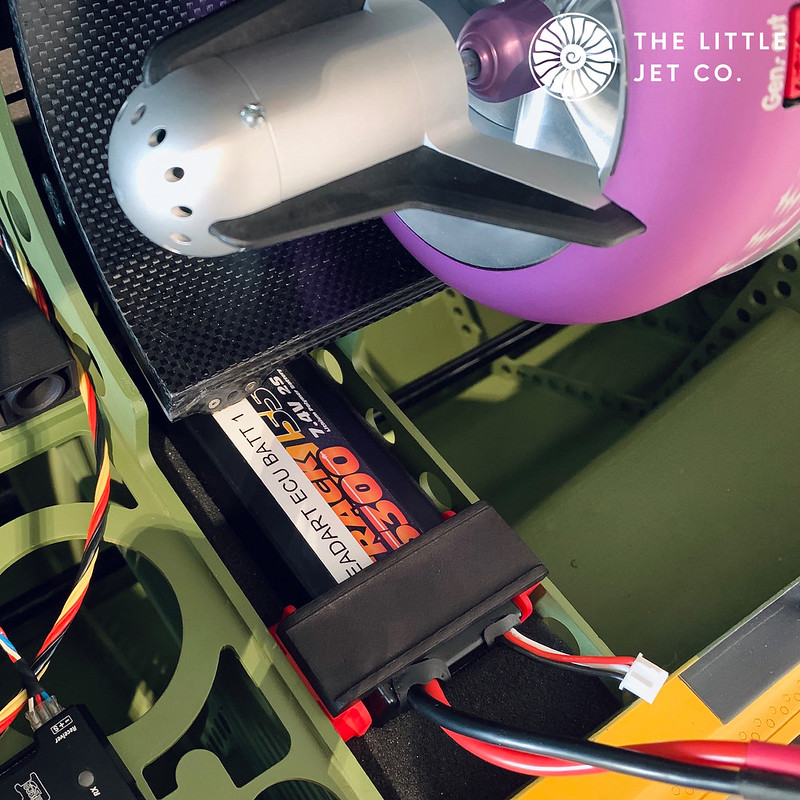

Following the theme of splash proofing anything electrical I have used high capacity RC car batteries in this case Overlander 7.4v 2S 5300 Lipos. These have worked well on our ARRMA cars which get drenched so should cope with this type of use well.

They are held in with a 3D printed latch, you just squeeze the red parts into the battery and it releases.

1FC90CFF-E03A-48DB-8622-B9A2FBC9406E

1FC90CFF-E03A-48DB-8622-B9A2FBC9406E by

Alex Jones, on Flickr

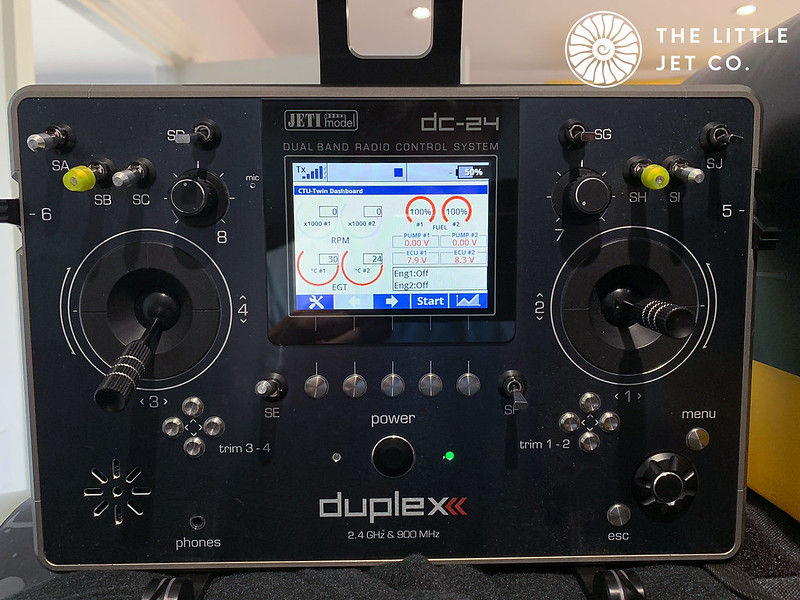

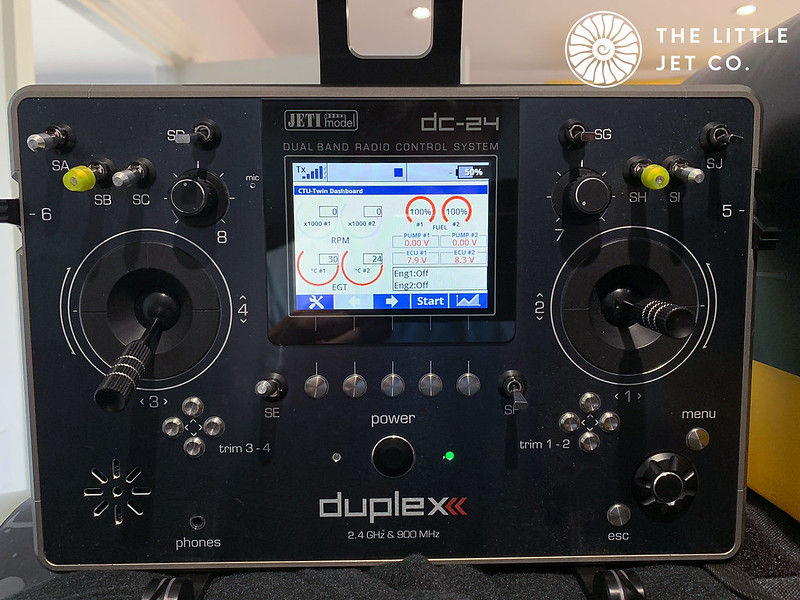

I’ve mentioned before we are using CTU’s from Digitech and the twin turbine dashboards works well. To make use of the fuel telemetry the pump factor needs to be calibrated. After running fuel through each pump I then adjust the pump factor so the fuel remaining reads zero as the main tank starts to empty.

A short video shows the result… The pump factor settings are found in the CTU menu.

https://youtu.be/R0JRNt77mlU 3328429A-6733-4BF5-8F7D-1BAEA8D103B4

3328429A-6733-4BF5-8F7D-1BAEA8D103B4 by

Alex Jones, on Flickr

I normally only fill the fuel systems on my jets at a rate equivalent to full thrust, It can no doubt cope with more but this way I’m sure I won’t over pressure the tank.

1A0D14DD-C199-4FDE-9E68-637F9F545D88

1A0D14DD-C199-4FDE-9E68-637F9F545D88 by

Alex Jones, on Flickr

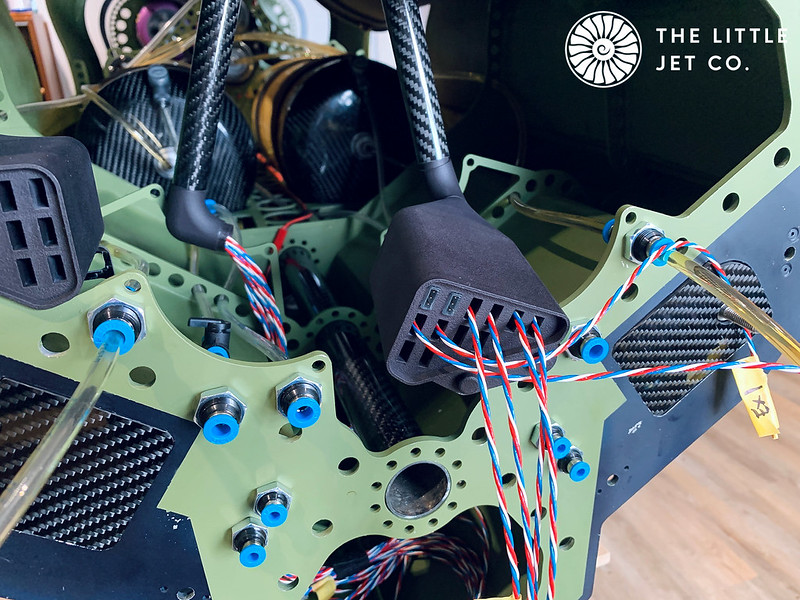

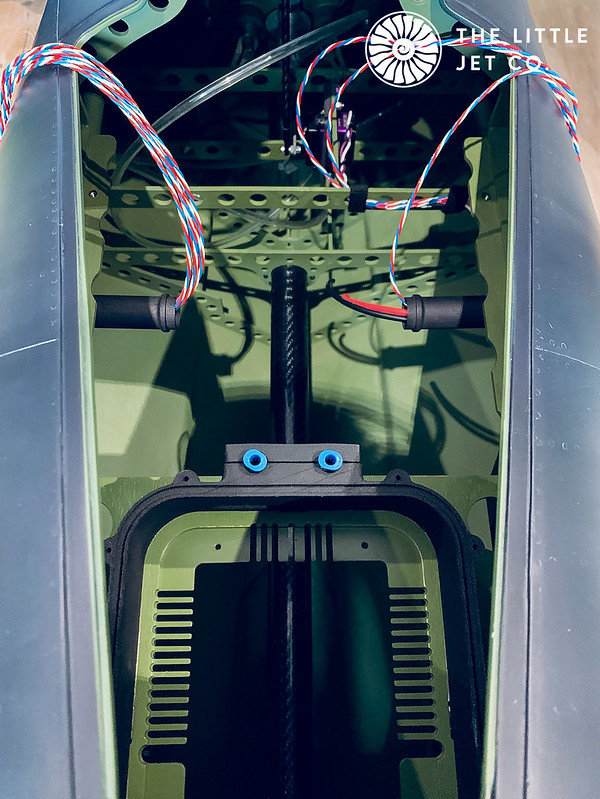

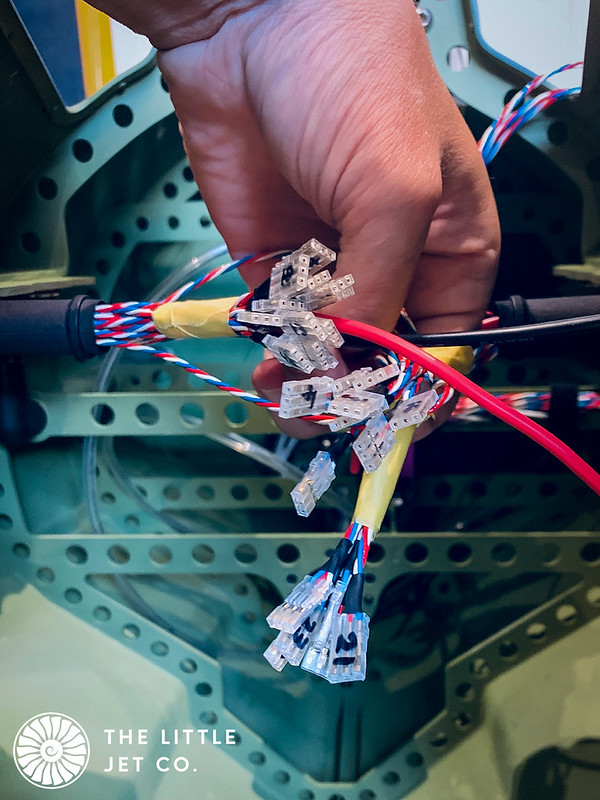

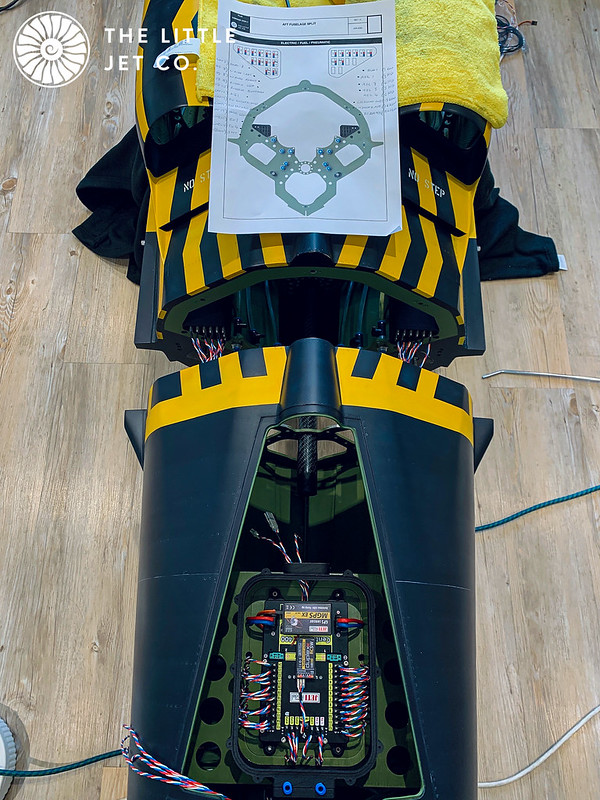

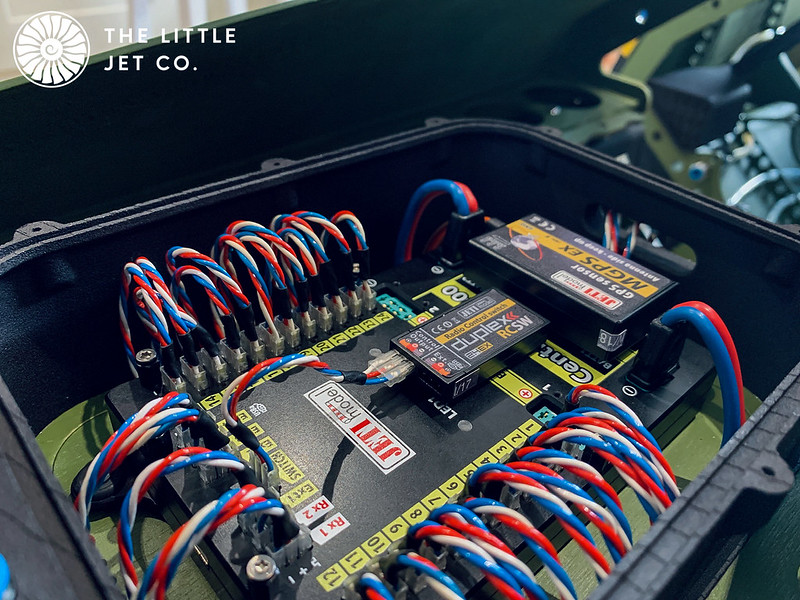

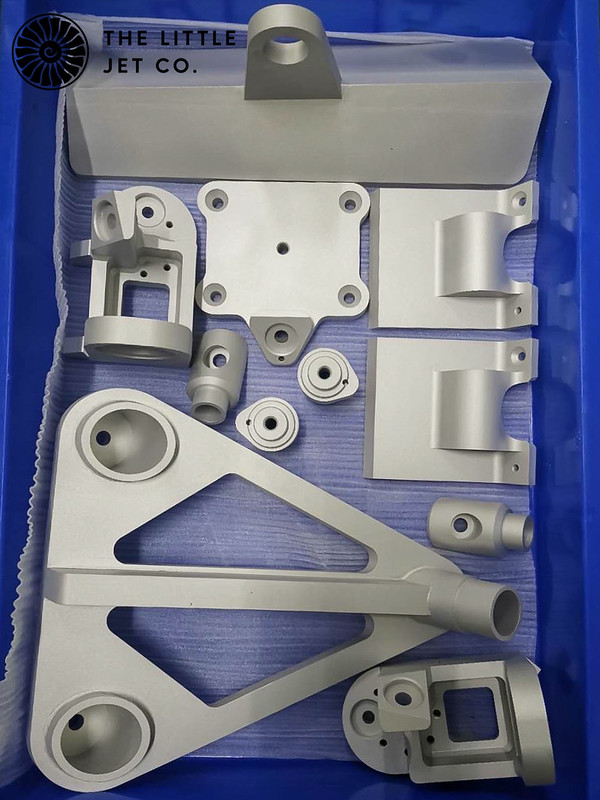

While Ive been working on this I have come up with a plan and designed some components that will allow us to easily assemble the fuselage halves and join the electrics easily and seal them from any water. The start of the process below.

34362D71-D36E-4949-A7F0-F639D9D142BD

34362D71-D36E-4949-A7F0-F639D9D142BD by

Alex Jones, on Flickr

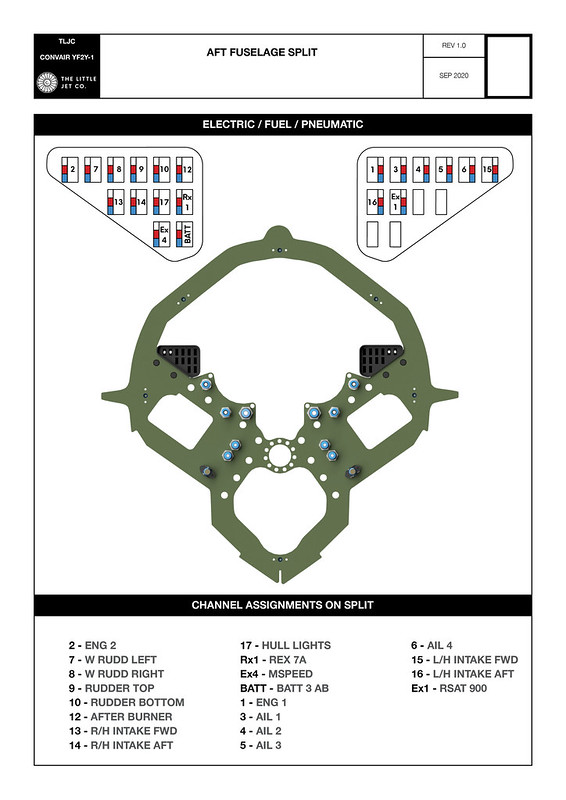

43696B13-B225-4C32-9D19-752CB334EB62 by Alex Jones, on Flickr

43696B13-B225-4C32-9D19-752CB334EB62 by Alex Jones, on Flickr A3DECA13-799D-40AF-A224-F8C3F2E24892 by Alex Jones, on Flickr

A3DECA13-799D-40AF-A224-F8C3F2E24892 by Alex Jones, on Flickr